Overview

The compact modular design ensures optimal hook approach, adhering to FEM/DIN/ISO standards.

Operational efficiency is enhanced by eliminating counterweights. All variants up to 15t , come with a standard supply of Duty Class ISO M5/FEM 2m. The flange width is easily adjustable through threaded screws and fasteners. Standard inclusion of frequency inverters in both lifting and cross-travel movements ensures increased longevity of mechanical components. Speed control via inverters allows for selectable speeds, providing precise handling and smooth movement.

CLH Series Models

| Model NO |

Working Load (Tons) |

Lift Height (m) |

Reeving |

Speed (m/mm) |

FEM |

| CLH 0.5 |

0.5T |

6, 9, 12, 18, 24 |

2/1 |

2.5~10 |

2M |

| CLH 01 |

1T |

1.25~5 |

| CLH 02 |

2T |

| CLH 03 |

3T |

6, 9, 12 |

4/1 |

| CLH 05 |

5T |

1~4 |

| CLH 7.5 |

7.5T |

1.2~4.7 |

| CLH 10 |

10T |

| CLH 10 |

15T |

6/1 |

0.8~3 |

Single Girder Monorail Hoist Types

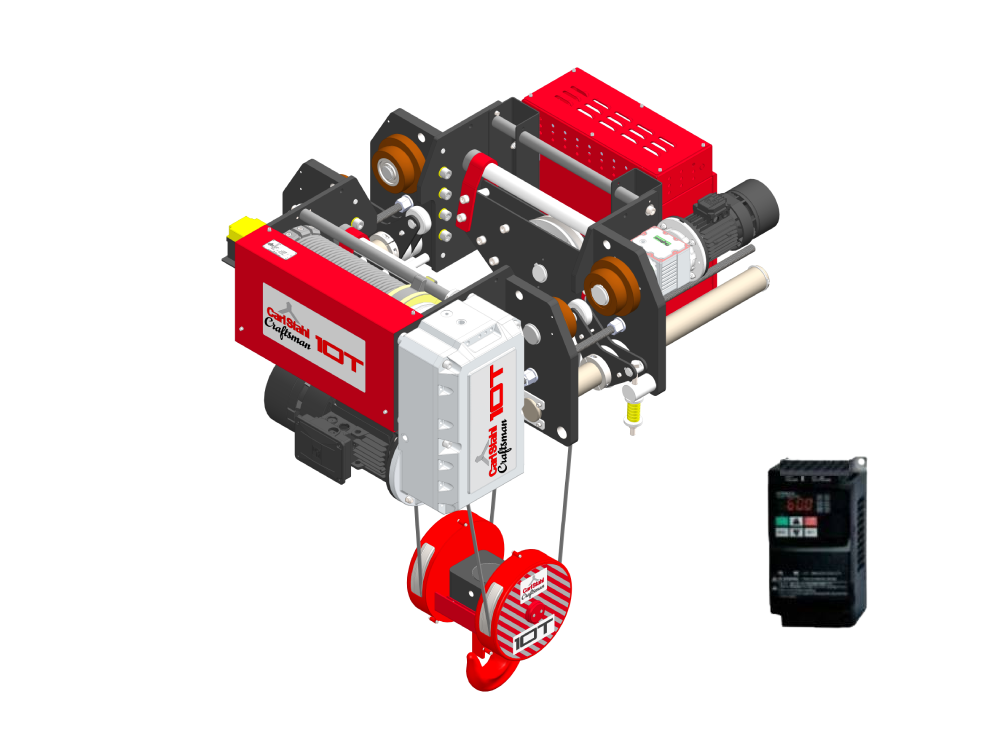

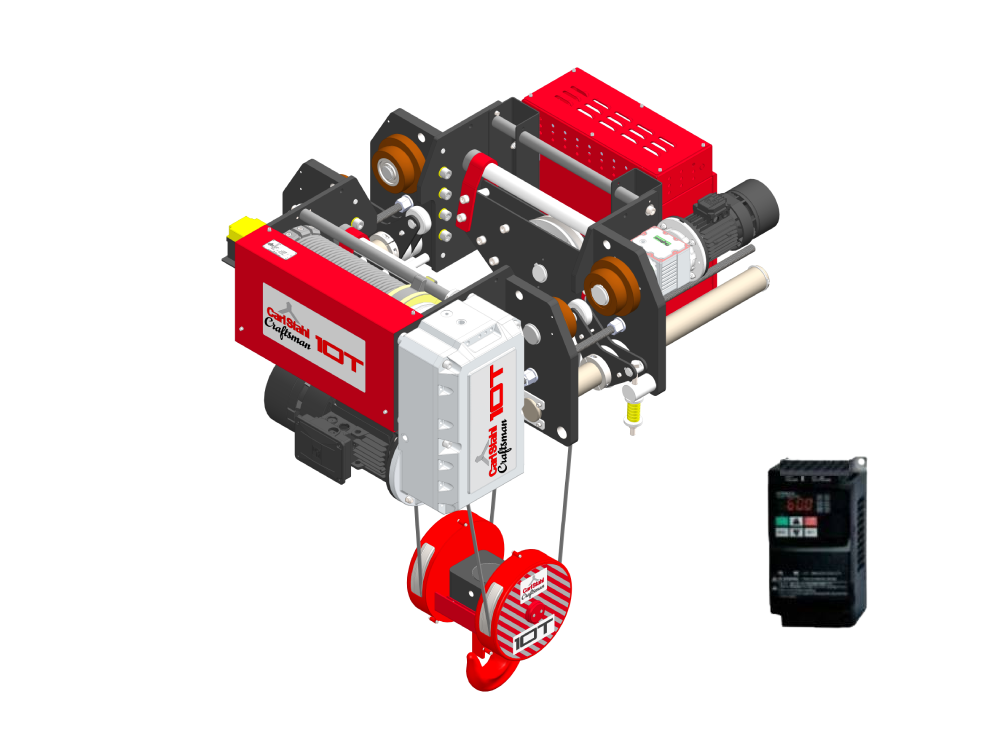

Low HeadRoom Hoist (Model: CLH-R)

Capacity: up to 10T

Technical Advantages

- Compact modular design provides maximum hook approach.

- Designed according to FEM / DIN / ISO standards.

- Counter weights are eliminated for better operational efficiency.

- Duty Class ISO M5 / FEM 2m as standard supply in all variants.

- Flange width: Smoothly adjustable with threaded screws and fasteners.

- Frequency inverters as standard in lifting and cross travel movements.

- Increased life of mechanical components.

- Speed control by inverter, selectable speeds.

- Precise handling and smoothness in movement.

Features

- Modular in construction with flexibility on falls interchange (4/1,2/1).

- Light weight and comparably less headroom.

- Forged hooks according to DIN standards.

- Flanged wheels to guide the runway beam.

- Travel machinery directly drives the wheels.

- Acceleration and deceleration by inverters to increase the life span of the components.

Safety

- Rope safety factor >= 5

- Motor over heating protection with thermistor.

- Double limit switch for up and down travel movement.

- Precise and accurate closed loop overload protection system (via.) VFD.

- Reliable load clamping by safety latch.

Technology

- Gear Box

- Rope Drum

- Rope Guide

- Rope

- Hook Block

- Rotary Limit Switch Equipment

- End Tie Assembly

- Variable Frequency Drive

- Cross Travel Machinery

- Hoisting & Travel Motor

- Wheel

Specifications

Standard Specifications

| Capacity Range |

500 Kg to 10000 Kg |

| Classification |

FEM 2m, 3m, 4m |

| Lifting Speed(m/min) |

1~10 M/Min (Frequency Controlled) |

| Travel Speed(m/min) |

5~20; Freqency Controlled

25/6; Contactor Controlled |

| Power Supply |

415Volts, 3 Phase, 50 Hz, AC Supply |

| Control Supply |

24 Volts, 50 Hz, DC Supply Frequency Controlled

48 Volts, 50 Hz, AC Supply Contactor Controlled |

| Ambient Temp. (°C) |

50°C Max |

| Application |

Indoor |

| Thermal Insulation Class |

F-Class |

| Motor Enclosure |

IP 54 |

| Brake Type |

Electromagnetic Disc Brake - AC/DC |

| Runway Beam |

ISMB 100~600 (or) Plate (Width may vary) |

| Hook |

DIN 15400 |

| Rope Drum |

Seamless pipe rope drum grooved as per DIN 15061 |

Description

Gear Box

- In-house precision machined Aluminium cast body for reduced weight.

- In-house hardened and Precision ground gears for smooth running and long life.

- Gears permanently immersed in synthetic oil for quiet, smooth and cool operation.

Rope Drum

- Designed for durability and life long.

- Constructed from a high quality seamless steel.

- Manufactured according to DIN-15061.

Rope Guide

- Heavy duty rope guide ensures positive rope scrolling.

- GGG 40 spheroidal cast iron material used to provide low wear and keeps the rope securely in the groove on the drum.

- Special guide spring is fitted between the wire rope and the guide to maintain the correct tightness of the rope on the drum.

Rope

- High strength Wire Rope provides high resistance to fatigue and wear.

- Compact strand structure and highly flexible steel core rope for long life.

- High wire rope / pulley diameter ratio increases the rope life span.

- Selected according to ISO 4308-1.

Hook Block

- Robust design for improved safety and handling.

- Rotating hook and pulley block with safety latch.

- High strength forged steel hook capable of 360 degree rotation.

- Machined sheave grooves for long rope life.

- Designed according to DIN-15400.

Rotary Limit Switch Equipment

- Automatic cut-off of the lifting and lowering motions in upper and lower limit positions.

- Cut-off position can be adjusted to suit the application.

- Provides Upper/Lower motion limit switch as standard option.

End Tie Assembly

- Precise and accurate closed loop overload protection system(Via) VFD as an standard feature

- Rope tension load cell are used as optional accessories to measure load force and provide overload protection.

Variable Frequency Drive

- Variable frequency drives being optimized with the hoist application to have a smother and safer operation of the cranes with flexibility of variable speeds match the application.

Cross Travel Machinery

- Travel machinery is specially designed for hoist application.

- Easy to remove without removing wheels.

- Case hardened and Precision ground gears for smooth running and long life.

- Gears permanently immersed in oil/grease for quiet, smooth and cool operation.

- Standard travelling speeds of 20 m/min (single speed) and 20/5 m/min {double speed) at 50Hz. Other travelling speeds can be also fitted upon request.

Hoisting & Travel Motor

- Heavy duty motor with an incorporated brake and fan cooled.

- The brake disc lining material is asbestos free with high friction coefficient and long lasting.

- Provided with IP 54 enclosure rating and F insulation class.

- On request we can provided with IP55 or IP 56 enclosure rating with H Class insulation.

- Thermistors fitted on windings of the motor for protection of windings in high temperature.

Wheel

- Single flanged wheels for monorail hoist and double flange for crab hoist.

- The wheels are totally machined, and made of spheroidal cast material SG-700/2.

- Ball / Spherical Roller / Taper Roller bearings are used for high life.

- Modular design to suit different mounting positions.

- Easy removal and maintenance.